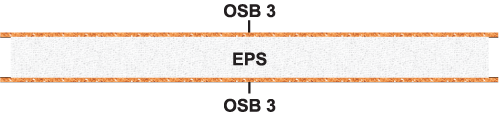

The putting-together houses RichHouse are built with constructively insulting pannels, which are a flatting made of expanded polystyrene, which on the both sides has glued OSB flattings.

OSB (Oriented Strand Board) – wooden flatting with wooden particles arranged longitudinally (100% softwood) in the front layers and arranged transversely in the middle layer. For the manifacturing of the pannels it is used OSB 3(waterproof) which is 12mm thick, 1250mm wide and 2500mm long.

| Flexural strength: | 22 N/mm2 |

| Elasticity: | 3500 N/mm2 |

| Strength ripping: | 0.32 N/mm2 |

| Swelling after 24 hours: | 15% |

| Density: | 640 ±10% |

Glue – mono glue without solvent. It is based on polyurethane.

| Period bond: | 25-35 minutes |

| Density: | 1.15 g/cm3 |

| Viscosity at 20C: | 8.000 ± 2.500 mPa/s |

| Consumption: | 150-400 g/m2 |

Expanded polystyrene EPS – expanded polystyrene with density of 20-25kg/m3 and thermal conductivity λ = 0.033 – 0.035. The thickness of the used plates is 50,100,150 and 200mm. The material is self-extinguishing.

OSB flatting is glued to the expanded polystyrene with polyurethane glue under the pressure of 18-ton press.